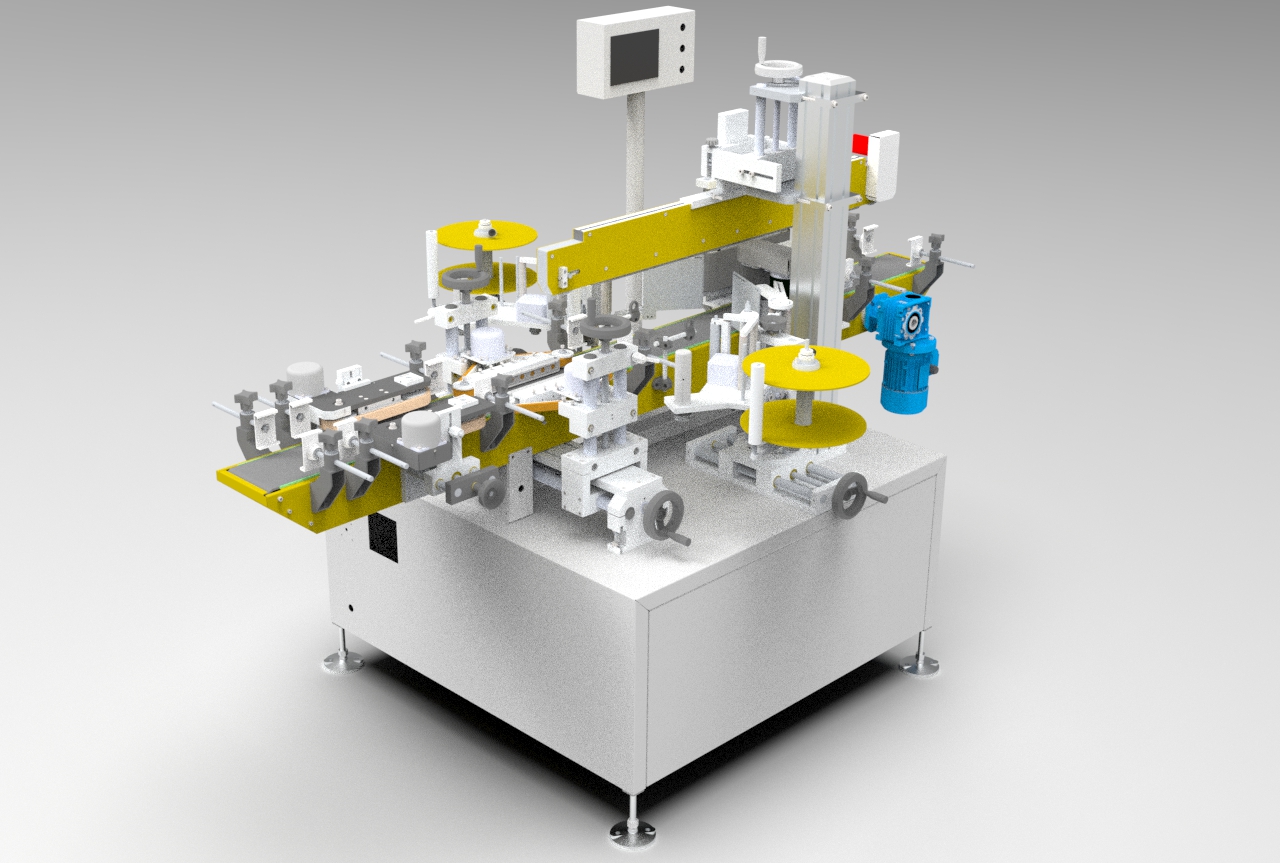

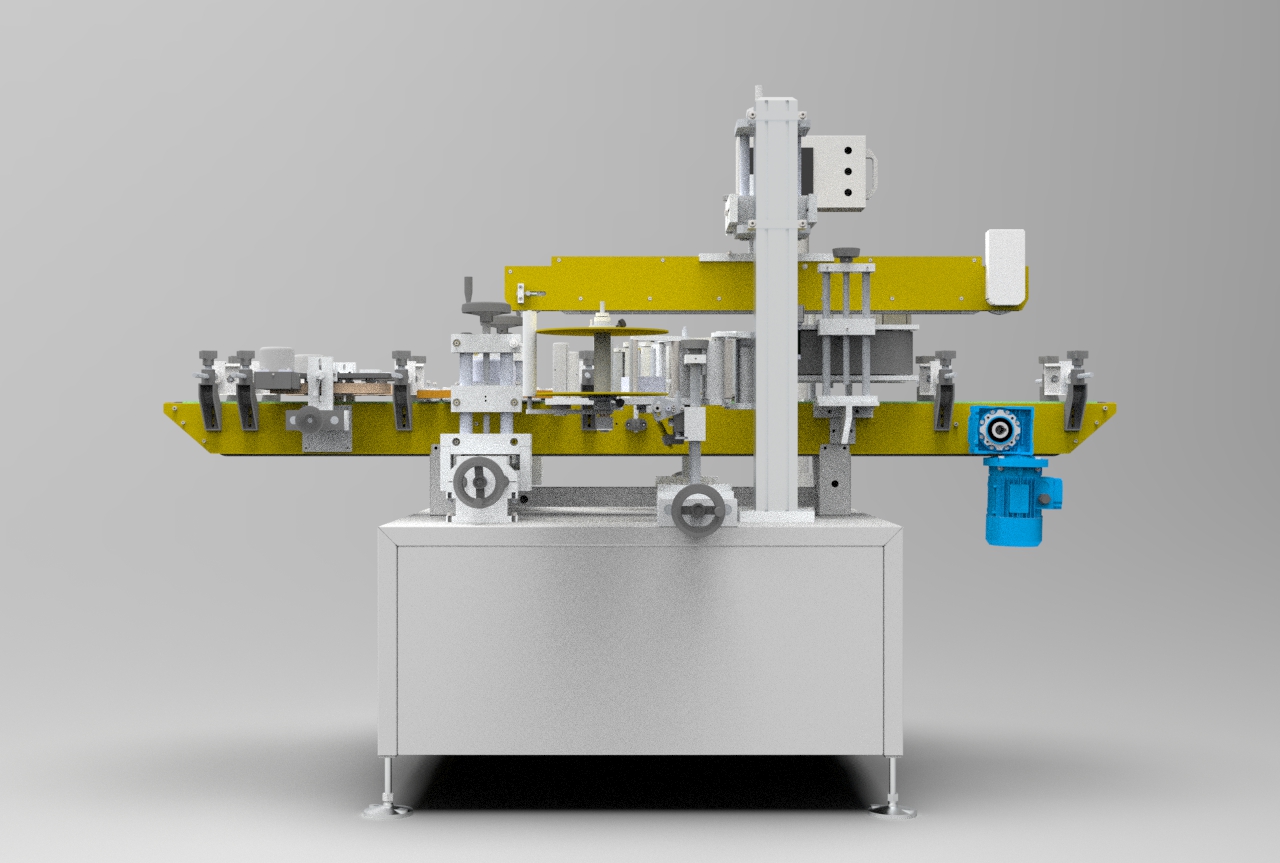

3D design of double-sided labeling machine

A complete automatic labeling machine is a device that can stick rolled paper labels or metal foil labels on bottles, products, or specified packaging. The back of the label has its adhesive and is regularly arranged on the glossy backing paper.

The feeder or label stripping mechanism on the labeling machine can automatically peel it off. The full-automatic labeling machine locates the PCB or product flowing from the previous link on the assembly line and uses visual methods to confirm its coordinates. After the suction head of the full-automatic labeling machine takes materials from the feeder, it takes photos on the bottom camera to confirm the label coordinates.

According to the internal algorithm of the machine, it aligns the label with the coordinates of the location to be pasted and then pastes it on the product, which has reached a high precision. The full-automatic labeling machine can complete the PCB surface pasting, The SMT industry is now widely used to replace manual labor in various operations such as pasting on the original PCB surface, pasting on other planes, pasting on one or more sides of the package, pasting on a cylinder, pasting on a partially covered or fully covered cylinder, and pasting on depressions and corners.

This model is a commonly used double-sided automatic labeling machine on the packaging production line. The labeling object can be a packaging box or a product of corresponding specifications. The overall dimension of the equipment is 3500 × two thousand five hundred and sixteen × 2300mm, the upper front, middle and rear sections of the conveyor belt contain corresponding limit adjustment mechanisms, which can achieve accurate labeling and high reliability.

This 3D design by SolidWorks2017, the file totally 118 MB, including step file for other 3D software open.